Scope of application

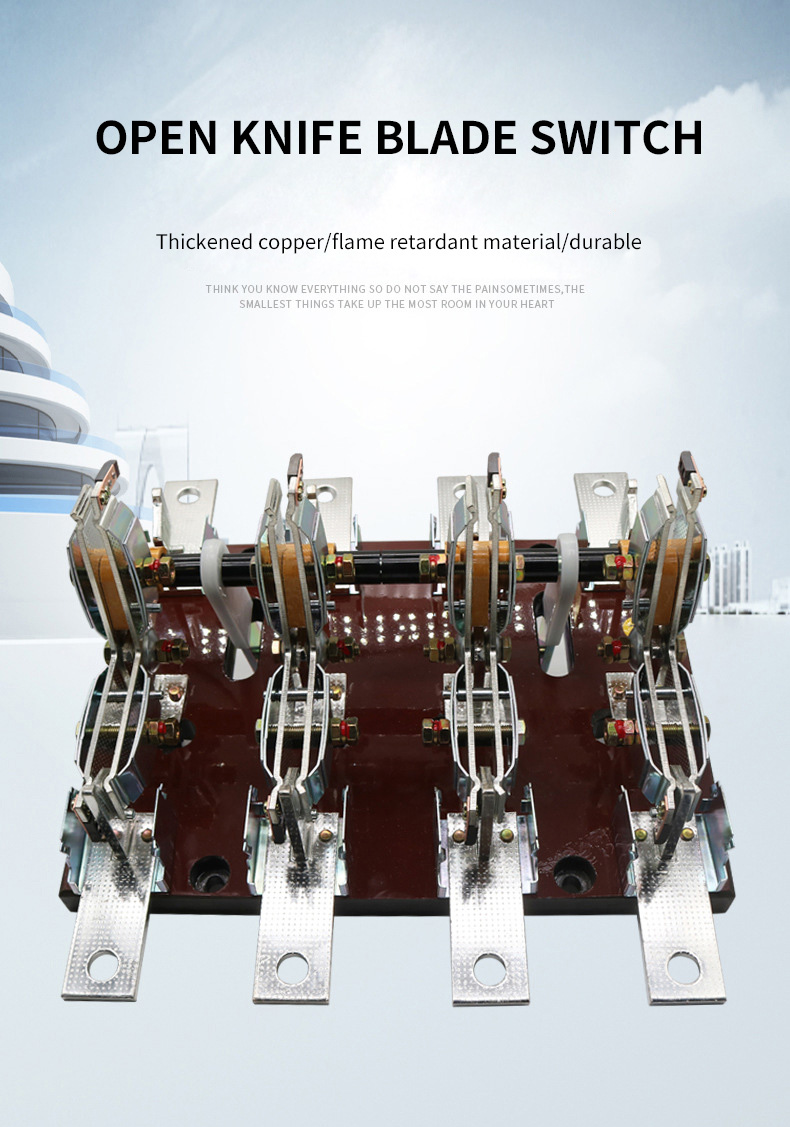

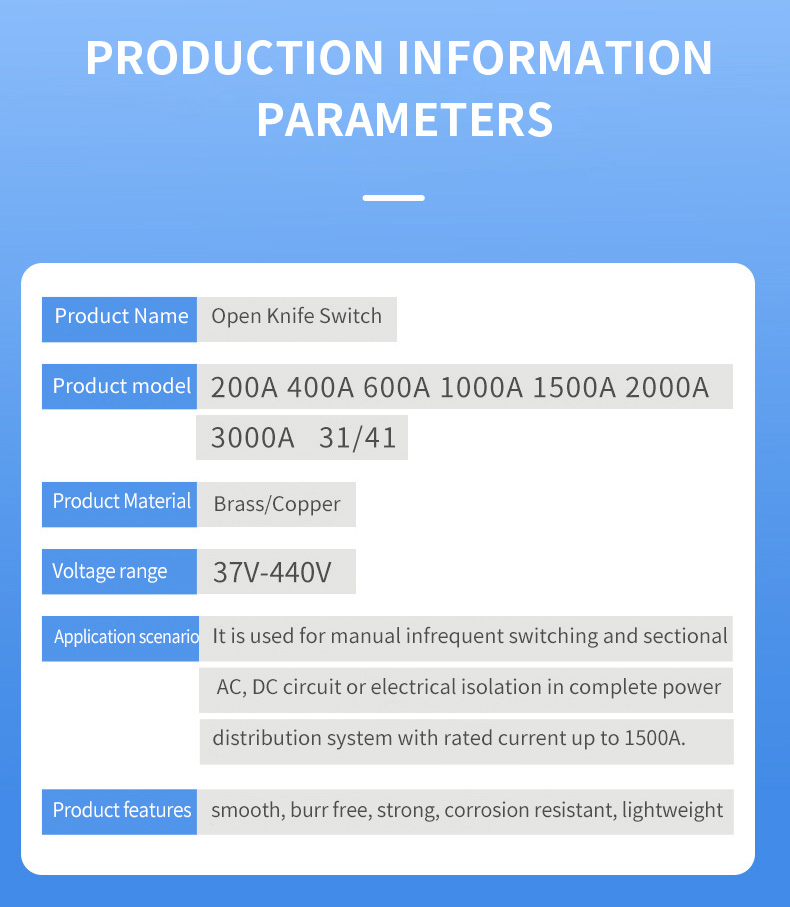

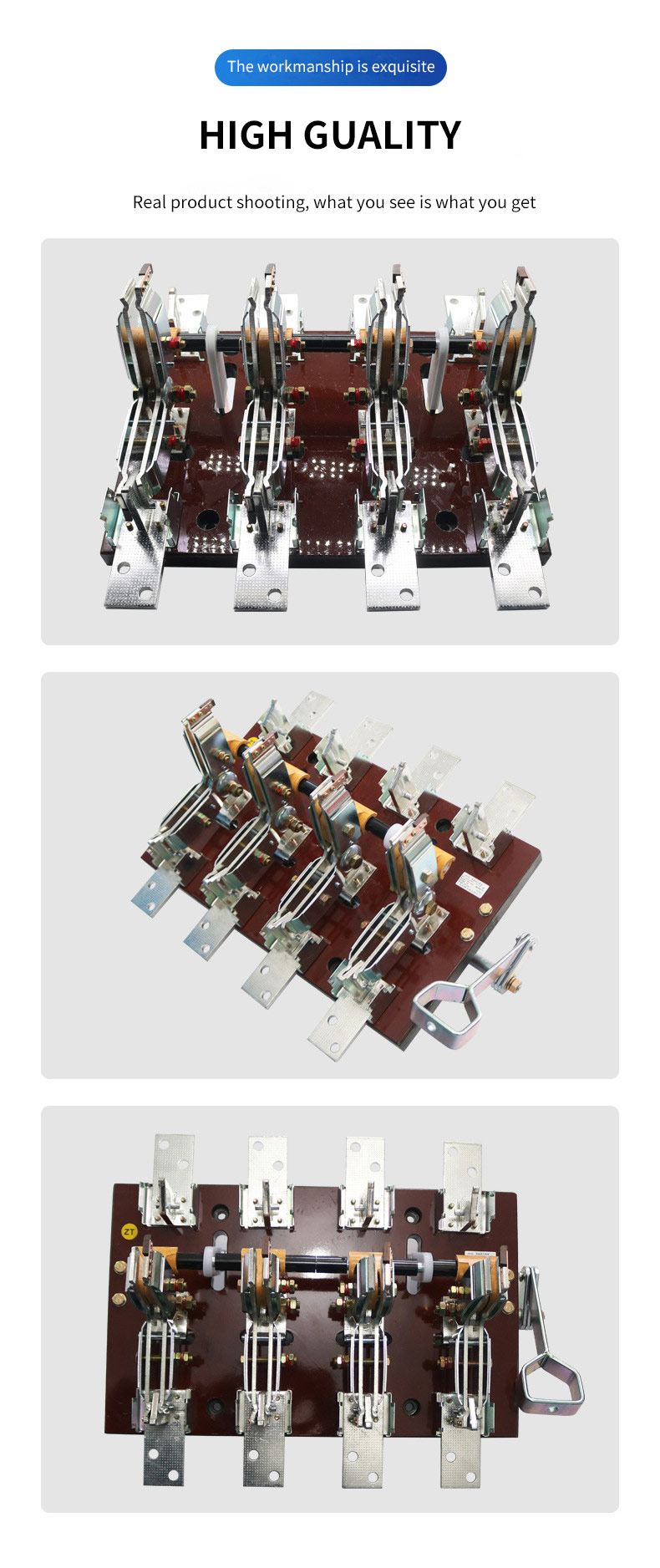

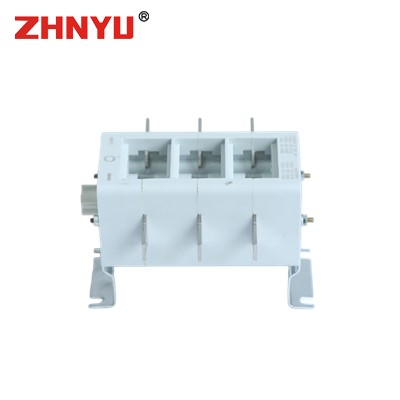

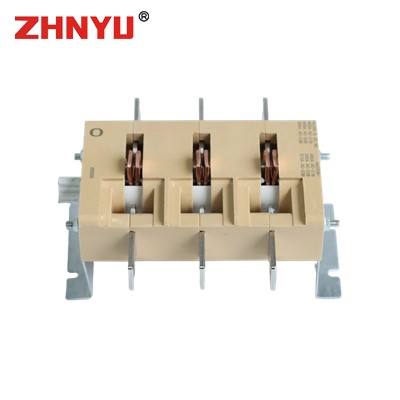

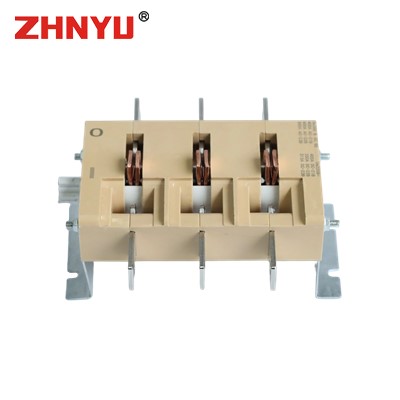

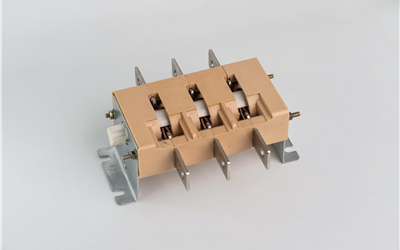

Knife Blade Switch HD series and HS series open knife switches and knife shaped transfer switches (hereinafter referred to as switches) are applicable to complete sets of power distribution devices with AC 50Hz, rated voltage up to AC690V and rated current up to 3000A. They are used as infrequent manual connection and disconnection of AC circuits or as isolation switches.

The central handle type switch is mainly used in the power station, which does not cut off the circuit with current and is used as an isolating switch.Knife Blade Switch

The central lever operating mechanism switch is mainly used in the switchgear with front operation and rear maintenance, and the operating mechanism is installed in the front.Knife Blade Switch

The side and front lever operated mechanism switch is mainly used in the switch cabinet for side and front operation and front maintenance. The operating mechanism can be installed on both sides of the cabinet.Knife Blade Switch

The switch equipped with arc extinguishing chamber can cut off the current load, and other series of knife switches are only used as disconnectors.Knife Blade Switch

This product conforms to IEC60947-3 GB14048.3 standard.

Read on what is isolator switch?

Normal working and installation conditions

The ambient air temperature is not higher than +40 ℃ and not lower than -5 ℃.Knife Blade Switch

The altitude of the installation site shall not exceed 2000m.Knife Blade Switch

Humidity: when the maximum temperature is +40 ℃, the relative humidity of the air does not exceed 50%. At a lower temperature, a higher relative humidity can be allowed, such as 90% at 20 ℃. Corresponding measures should be taken for the occasional condensation due to temperature changes.Knife Blade Switch

The pollution level of the surrounding environment is level 3.Knife Blade Switch

The switch shall be installed in a place without significant shaking, shock vibration and rain and snow invasion. At the same time, the installation site shall be free of explosive dangerous media, and the media shall be free of gas and dust that are sufficient to corrode metal and damage insulation.Knife Blade Switch.

|

Processing mode of base plate: Machining (rubber plate, epoxy plate) |

||||||||||||||||||

|

Specification and model |

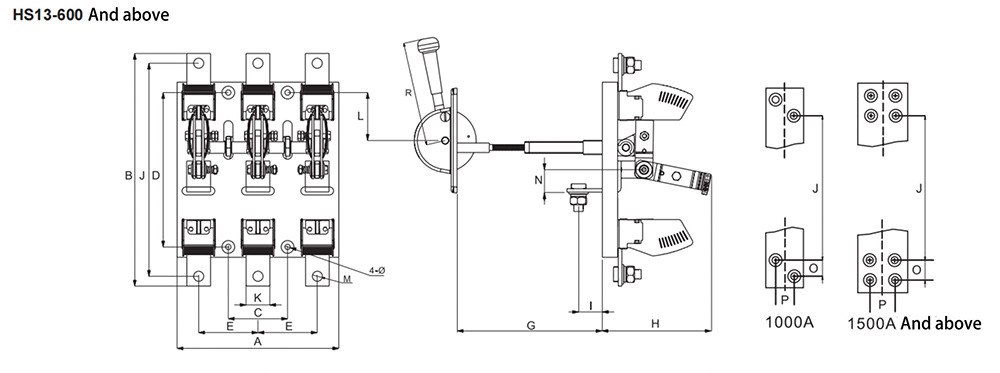

Overall dimension |

Installation dimension |

Handle opening size |

|||||||||||||||

|

|

A |

B |

E |

H |

G |

R |

J |

K |

L |

I |

O |

P |

M |

Φ |

C |

D |

S |

T |

|

HS13-200/31 |

210 |

270 |

80 |

160 |

245~265 |

175 |

210 |

/ |

75 |

26 |

/ |

/ |

8 |

7 |

80 |

240 |

100 |

146 |

|

HS13-200/41 |

290 |

270 |

80 |

160 |

245~265 |

175 |

130 |

/ |

75 |

26 |

/ |

/ |

8 |

7 |

160 |

240 |

100 |

146 |

|

HS13-400/31 |

242 |

300 |

90 |

180 |

245~265 |

175 |

166 |

/ |

65 |

29 |

/ |

/ |

12 |

7 |

90 |

240 |

100 |

146 |

|

HS13-400/41 |

330 |

300 |

90 |

180 |

245~265 |

175 |

166 |

/ |

65 |

29 |

/ |

/ |

12 |

7 |

180 |

240 |

100 |

146 |

|

HS13-600/31 |

270 |

392 |

100 |

185 |

245~265 |

175 |

359 |

40 |

68 |

37 |

/ |

/ |

16 |

9 |

100 |

240 |

100 |

146 |

|

HS13-600/41 |

370 |

392 |

100 |

185 |

245~265 |

175 |

359 |

40 |

68 |

37 |

/ |

/ |

16 |

9 |

200 |

240 |

100 |

146 |

|

HS13-1000/31 |

330 |

442 |

120 |

230 |

245~265 |

230 |

358 |

50 |

62 |

23 |

26 |

26 |

2-12 |

9 |

120 |

240 |

100 |

146 |

|

HS13-1000/41 |

450 |

442 |

120 |

230 |

245~265 |

230 |

358 |

50 |

62 |

23 |

26 |

26 |

2-12 |

9 |

240 |

240 |

100 |

146 |

|

HS13-1500/31 |

360 |

484 |

130 |

255 |

245~265 |

230 |

384 |

70 |

73 |

23 |

35 |

35 |

4-12 |

9 |

130 |

260 |

130 |

170 |

|

HS13-1500/41 |

500 |

484 |

130 |

255 |

245~265 |

230 |

384 |

70 |

73 |

23 |

35 |

35 |

4-12 |

9 |

260 |

260 |

130 |

170 |

|

HS13-1500/30 |

360 |

484 |

130 |

255 |

245~265 |

230 |

384 |

70 |

73 |

23 |

35 |

35 |

4-12 |

9 |

130 |

260 |

130 |

170 |

|

HS13-1500/40 |

500 |

484 |

130 |

255 |

245~265 |

230 |

384 |

70 |

73 |

23 |

35 |

35 |

4-12 |

9 |

260 |

260 |

130 |

170 |

|

HS13-2000/30 |

500 |

474 |

180 |

230 |

245~265 |

280 |

358 |

97 |

62 |

44 |

40 |

55 |

4-12 |

9 |

180 |

260 |

130 |

170 |

|

HS13-2000/40 |

680 |

474 |

180 |

230 |

245~265 |

280 |

358 |

97 |

62 |

44 |

40 |

55 |

4-12 |

9 |

360 |

260 |

130 |

170 |

|

HS13-2000/31 |

550 |

442 |

180 |

230 |

245~265 |

280 |

358 |

2-50 |

62 |

23 |

26 |

26 |

2-12 |

9 |

180 |

260 |

130 |

170 |

|

HS13-2000/41 |

730 |

442 |

180 |

230 |

245~265 |

280 |

358 |

2-50 |

62 |

23 |

26 |

26 |

2-12 |

9 |

360 |

260 |

130 |

170 |

|

HS13-3000/30 |

600 |

534 |

200 |

260 |

245~265 |

280 |

381 |

117 |

73 |

40 |

45 |

68 |

4-16 |

9 |

200 |

260 |

130 |

170 |

|

HS13-3000/40 |

790 |

534 |

200 |

260 |

245~265 |

280 |

381 |

117 |

73 |

40 |

45 |

68 |

4-16 |

9 |

400 |

260 |

130 |

170 |

|

HS13-3000/31 |

720 |

484 |

230 |

255 |

245~265 |

280 |

384 |

2-70 |

73 |

23 |

35 |

35 |

2-12 |

9 |

230 |

260 |

130 |

170 |

|

HS13-3000/41 |

920 |

484 |

230 |

255 |

245~265 |

280 |

384 |

2-70 |

73 |

23 |

35 |

35 |

2-12 |

9 |

460 |

260 |

130 |

170 |

|

Processing mode of base plate: Machining (rubber plate, epoxy plate) |

||||||||||||||||

|

Specification and model |

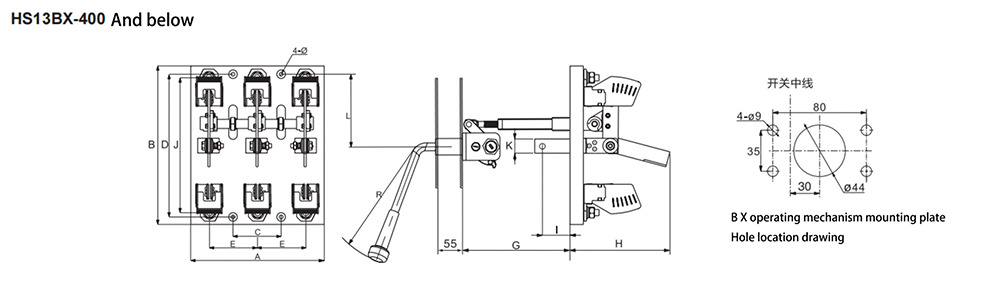

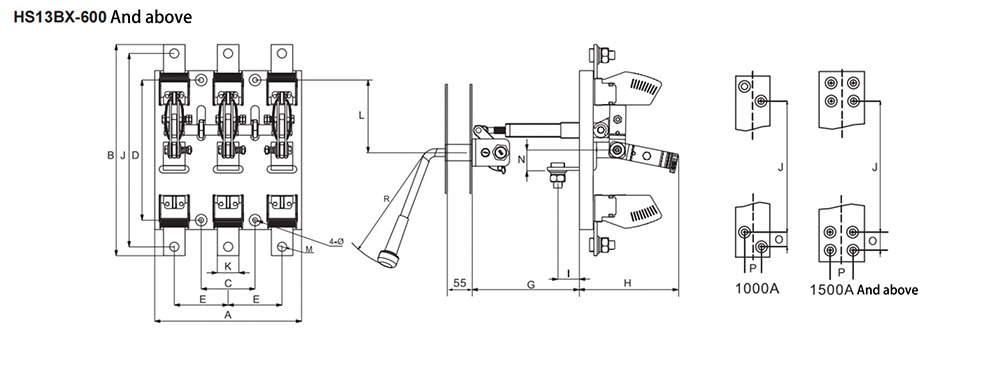

Overall dimension |

Installation dimension |

||||||||||||||

|

|

A |

B |

E |

H |

G |

R |

J |

K |

L |

I |

O |

P |

M |

Φ |

C |

D |

|

HS13BX-200/31 |

210 |

270 |

80 |

160 |

215~235

|

330 |

210 |

/ |

110 |

26 |

/ |

/ |

8 |

7 |

80 |

240 |

|

HS13BX-200/41 |

290 |

270 |

80 |

160 |

215~235

|

330 |

210 |

/ |

110 |

26 |

/ |

/ |

8 |

7 |

160 |

240 |

|

HS13BX-400/31 |

242 |

300 |

90 |

180 |

215~235 |

330 |

256 |

/ |

110 |

29 |

/ |

/ |

12 |

7 |

90 |

240 |

|

HS13BX-400/41 |

330 |

300 |

90 |

180 |

215~235

|

330 |

256 |

/ |

110 |

29 |

/ |

/ |

12 |

7 |

180 |

240 |

|

HS13BX-600/31 |

270 |

392 |

100 |

185 |

215~235

|

330 |

359 |

40 |

110 |

37 |

/ |

/ |

16 |

9 |

100 |

240 |

|

HS13BX-600/41 |

370 |

392 |

100 |

185 |

215~235 |

330 |

359 |

40 |

110 |

37 |

/ |

/ |

16 |

9 |

200 |

240 |

|

HS13BX-1000/31 |

330 |

442 |

120 |

230 |

240~260 |

330 |

358 |

50 |

105 |

23 |

26 |

26 |

2-12 |

9 |

120 |

240 |

|

HS13BX-1000/41 |

450 |

442 |

120 |

230 |

250~270 |

330 |

358 |

50 |

105 |

23 |

26 |

26 |

2-12 |

9 |

240 |

240 |

|

HS13BX-1500/31 |

360 |

484 |

130 |

255 |

250~270 |

330 |

384 |

70 |

110 |

23 |

35 |

35 |

4-12 |

9 |

130 |

260 |

|

HS13BX-1500/41 |

500 |

484 |

130 |

255 |

250~270 |

330 |

384 |

70 |

110 |

23 |

35 |

35 |

4-12 |

9 |

260 |

260 |

|

HS13BX-1500/30 |

360 |

484 |

130 |

255 |

250~270 |

330 |

384 |

70 |

110 |

23 |

35 |

35 |

4-12 |

9 |

130 |

260 |

|

HS13BX-1500/40 |

500 |

484 |

130 |

255 |

245~265 |

330 |

384 |

70 |

110 |

23 |

35 |

35 |

4-12 |

9 |

260 |

260 |

|

HS13BX-2000/30 |

500 |

474 |

180 |

230 |

245~265 |

330 |

358 |

97 |

120 |

44 |

40 |

55 |

4-12 |

9 |

180 |

260 |

|

HS13BX-2000/40 |

680 |

474 |

180 |

230 |

245~265 |

330 |

358 |

97 |

120 |

44 |

40 |

55 |

4-12 |

9 |

360 |

260 |

|

HS13BX-2000/31 |

550 |

442 |

180 |

230 |

245~265 |

330 |

358 |

2-50 |

120 |

23 |

26 |

26 |

2-12 |

9 |

180 |

260 |

|

HS13BX-2000/41 |

730 |

442 |

180 |

230 |

245~265 |

330 |

358 |

2-50 |

120 |

23 |

26 |

26 |

2-12 |

9 |

360 |

260 |

|

HS13BX-3000/30 |

600 |

534 |

200 |

260 |

245~265 |

330 |

381 |

117 |

110 |

40 |

45 |

68 |

4-16 |

9 |

200 |

260 |

|

HS13BX-3000/40 |

790 |

534 |

200 |

260 |

245~265 |

330 |

381 |

117 |

110 |

40 |

45 |

68 |

4-16 |

9 |

400 |

260 |

|

HS13BX-3000/31 |

720 |

484 |

230 |

255 |

245~265 |

330 |

384 |

2-70 |

110 |

23 |

35 |

35 |

2-12 |

9 |

230 |

260 |

|

HS13BX-3000/41 |

920 |

484 |

230 |

255 |

245~265 |

330 |

384 |

2-70 |

110 |

23 |

35 |

35 |

2-12 |

9 |

460 |

260 |